Products

Main shaft sliding bearing

Simulation driven design - combining EHD with shaft dynamics

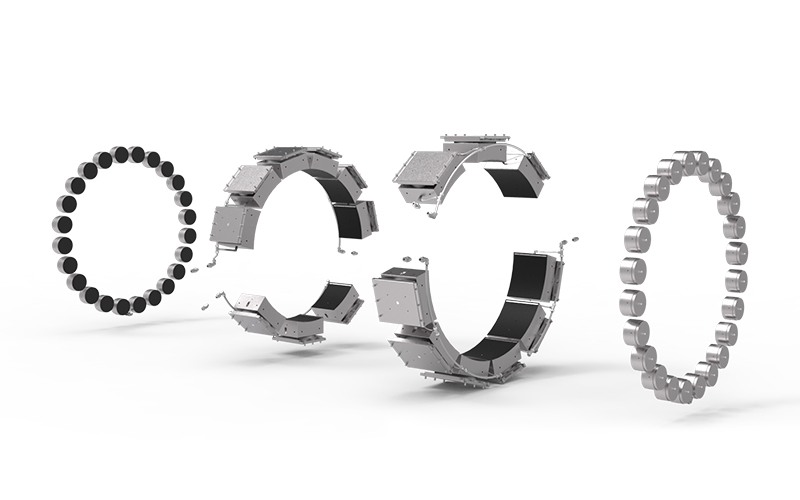

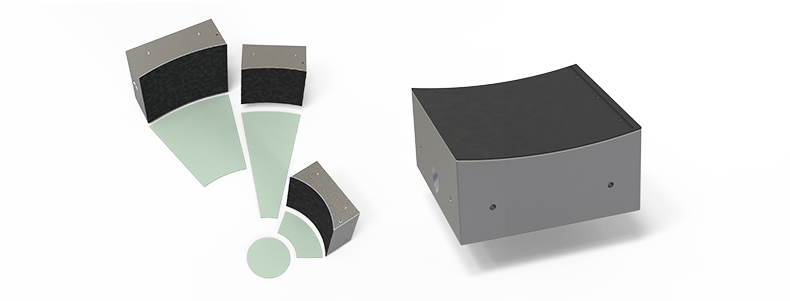

Segmented radial tile and thrust box design

Tower replacement and full lifecycle cost reduction

Facing deep sea and ultra large megawatt units

Intelligent bearing integrated solution

Sliding bearings have more significant advantages in the large-scale and far-reaching upgrading of the unit. Avoiding the difficulty of quenching heat treatment technology that increases with the geometric level as the size increases. Replacing bearings on the tower can save on lifting costs, especially the expensive cost of lifting ships for offshore units.

Hengchang sliding main bearings are designed in a block and modular manner, making the shaft system design of the unit more open and free;

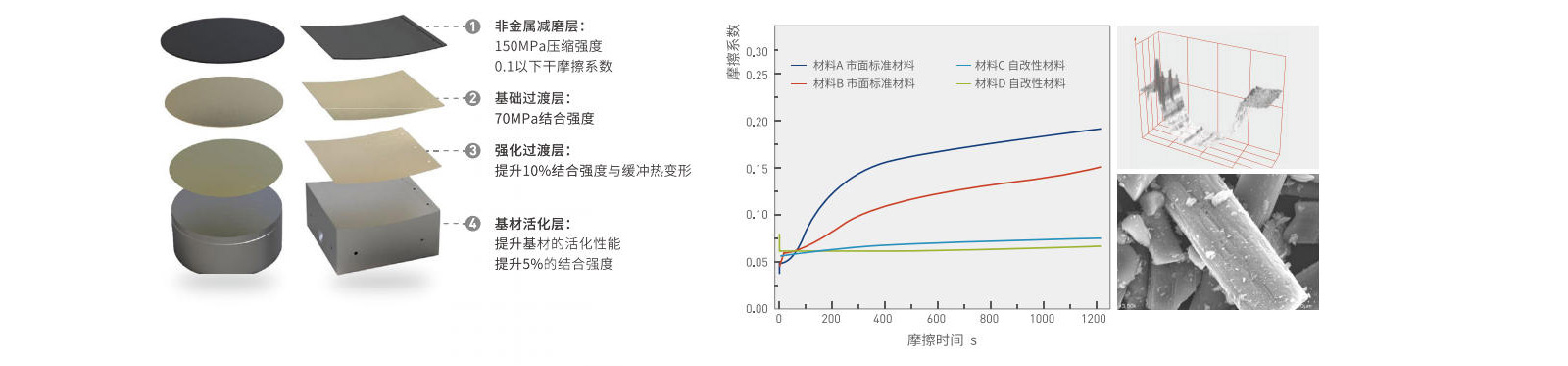

The PAEK modified material developed provides higher wear resistance and oil deficient self-lubricating performance;

The unique multi-layer composite structure enhances the load-bearing and reliability of the structure.

Main shaft radial tile

Sliding main bearing (radial) HCMBP series | |

substrate | Q235、Q355、 20 # steel, 45 # steel, 40Cr or customized by customers |

Overall dimensions | (100~500mm)*(100~500mm)*(50~200mm)Length × Width × Height |

Match spindle diameter | 500mm~3.50m |

Tolerance and accuracy | Outer circle accuracy: H6 Full runout: 0.02mm |

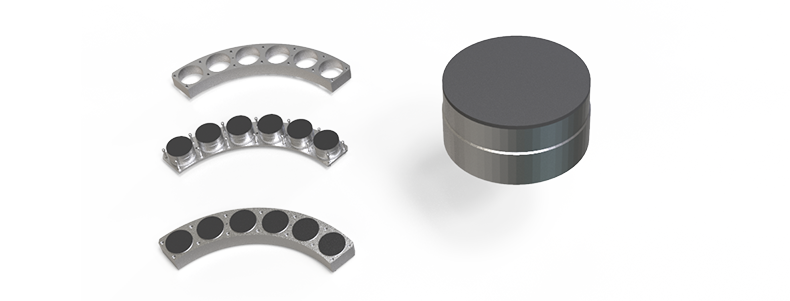

Bearing combination scheme | Non uniformly distributed tiltable elastic tile |

Bearing composite scheme | Substrate activation layer; Non metallic wear-resistant layer, basic transition layer, strengthened transition layer, basic activation layer |

Non metallic wear-resistant layer material | PAEK+ Carbon fiber modification |

Permanent deformation amount | <0.05mm |

binding strength | >70MPa |

Compressive strength (maximum allowable oil film pressure) | >150MPa |

Fatigue/creep performance | (1/3) Mechanical performance degradation of less than 20% after 2 million cycles of ultimate load |

Full life cycle wear and tear | <0.35 mm |

Oil supply plan | Tile independent oil supply system |

Adaptive lubrication | VG320 gear oil or customized lubricating oil |

Lubrication filtration accuracy | 10 um |

Operating Temperature | -40 ° C~80 ° C (preheating is required for non plating conditions below 0 ° C) |

coefficient of friction | Oil free dry friction self-lubricating<0.1 with oil lubrication (no oil film formed)<0.05 |

Adapt sensors | Optional temperature sensor; Load sensor; Wear sensor, membrane pressure sensor |

Main shaft thrust tile

Main shaft sliding bearing (thrust) HCMBT series | |

Technical Solution | Q235、Q355、 20 # steel, 45 # steel, 40Cr or customized by customers |

Overall dimensions | 平Cylindrical surface<400mm * 200mm inclined surface fan ring column<400mm * 400mm * 200mm |

Bearing composite scheme | Same radial tile |

performance metrics | Same radial tile |

Oil supply plan | Integrated thrust box, independent oil supply for tile block |

material properties

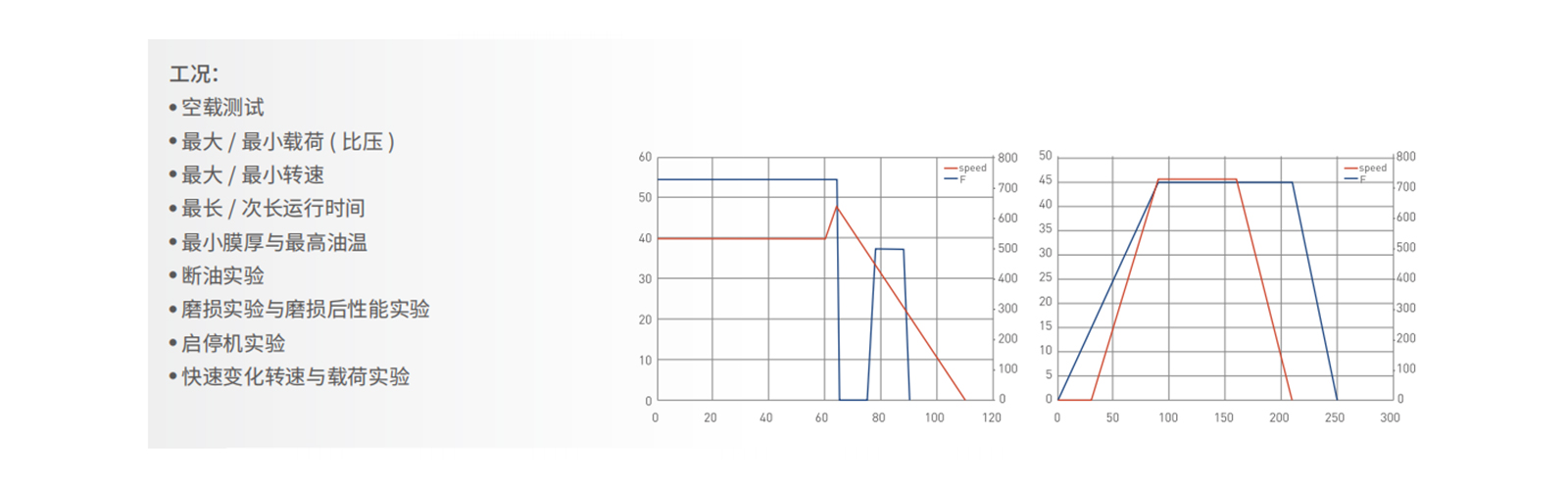

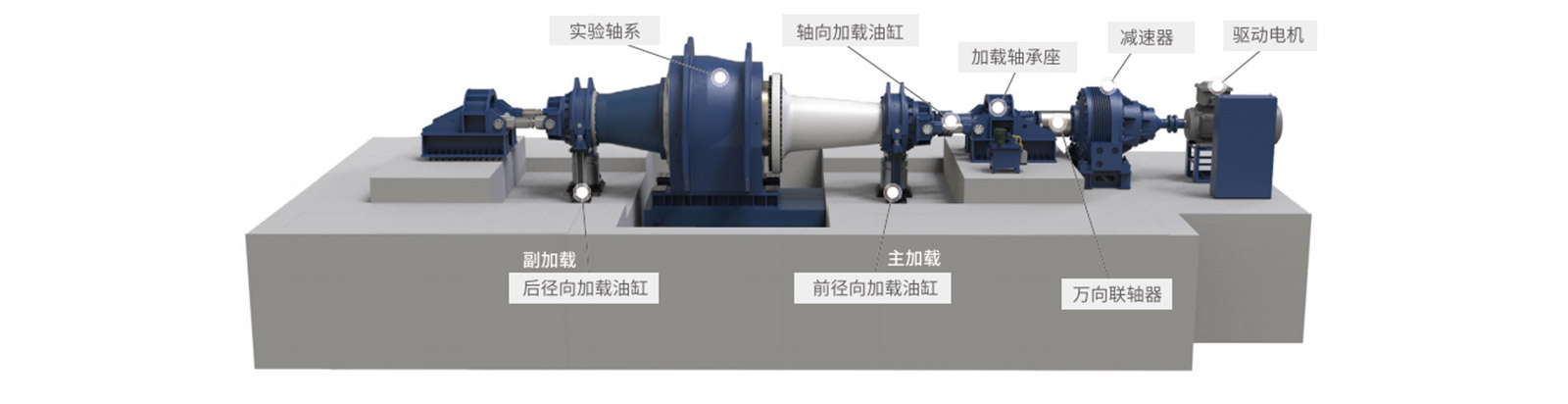

Bench test (full-size)